About

OzKem Pty Ltd is an Australian company specialising in corrosion protection for HVAC and Refrigeration Coils.

Coating Technologies

OzKem has developed two distinct coating technologies.

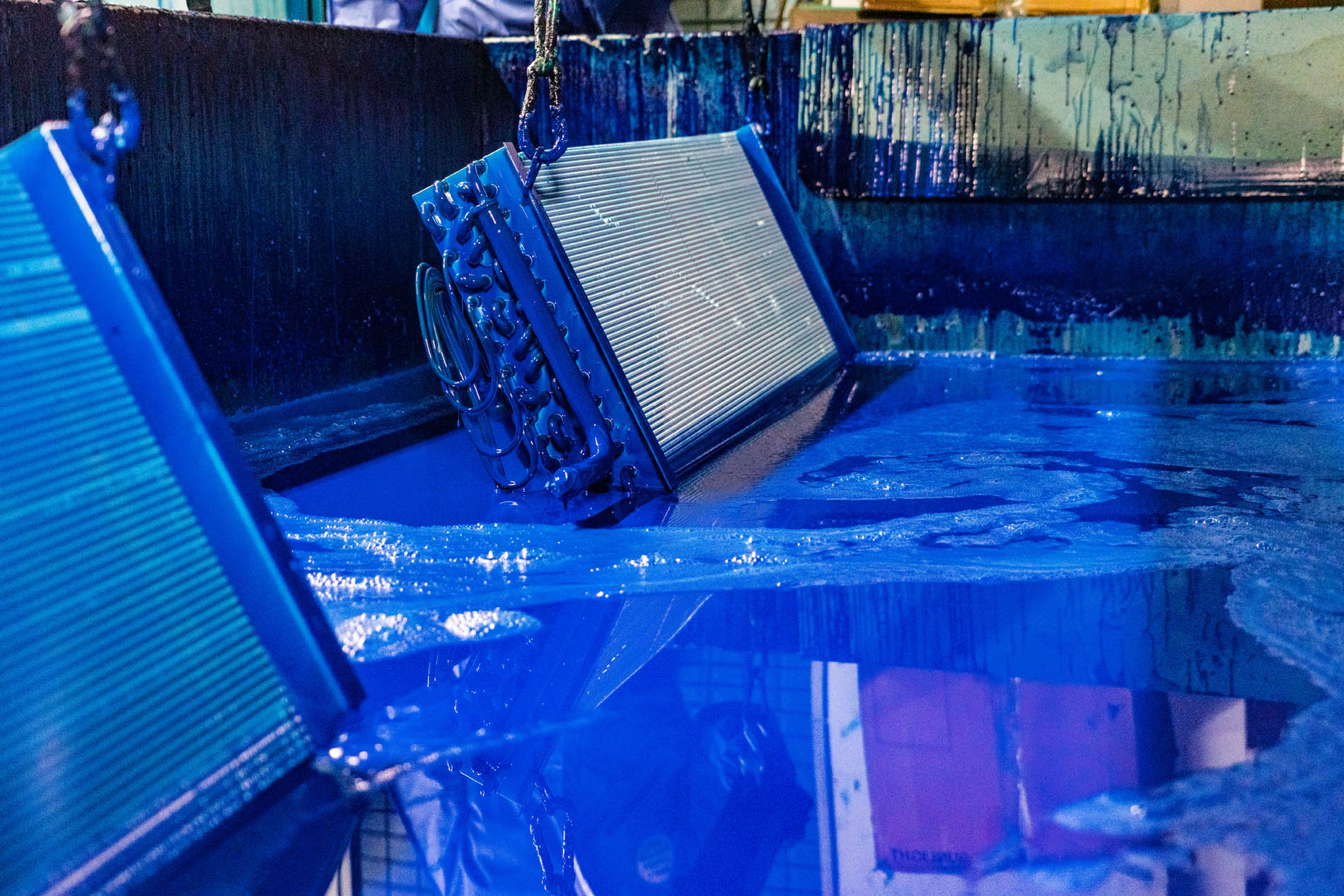

1. DIP COATING ECRA-SHM

A water based self-etching epoxy resin is supplied various colours at the required viscosity used for the coating of all ferrous and non-ferrous metals (as used in A/C coil manufacture) to give long term corrosion protection. The coating cures to a thin high gloss super hydrophobic finish perfect for all heat exchange surfaces.

Advantages

The coating provides protection from environmental and chemical exposures. It is a long-term protective coating that improves the long-term efficiency (structural and performance) of the system. The efficiency improvements come from four distinct features of the product.

SUPER Hydrophobic

The permanent super hydrophobic surface improves condensation characteristics and allows for faster run off of the condensate which improves heat exchange. The super hydrophobic surface also reduces dirt and dust consolidation reducing cleaning of the coil.

Corrosion Protection

The entire surface of the coil is protected, including tubes, which remain free of corrosion allowing the coil to maintain its long-term heat exchange efficiency.

Reduce Mould and Bacteria

The coating contains permanent Ag+ technology (Ag+ = Silver ion) reducing mould and bacteria growth within the coil. The coil stays clean and free of micro-biological contamination. A clean dry, bio-film free coil uses far less energy than a wet dirty coil.

Very Thin

The coating is only 6-8 microns which does not affect heat exchange or air flow

2. SPRAY COATING ECRA-DTM

Direct to metal high gloss water based acrylic copolymer specifically designed for use in industrial and marine HVAC coils, micro-channel coils and refrigeration coils to stop corrosion from salt and industrial pollution. The coating exhibits excellent performance properties, including high gloss, anti-corrosion resistance and excellent salt spray resistance.

The formulation is a new HYBRID Resin which allows the addition of special properties which increase both the corrosion resistance and the overall performance of the heat exchange surface. The resin matrix is a tightly crosslinked coating which adheres tightly to all metal substrates.

The formulation, in addition, provides hydrophobic and anti-microbial (silver ion) film characteristics suitable for both the topcoat and maintenance applications.

The coating can be applied to previously coated fins to increase protection. Coatings such as Heresite, BLYGOLD and E-COAT can be coated without pretreatment.